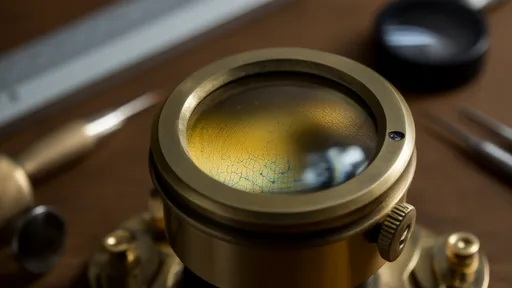

The world of pearl cultivation and trade has long been revered for its meticulous attention to detail, where even the slightest variations in color can determine the value and appeal of these lustrous gems. In recent years, Japan, a global leader in pearl production, has taken a groundbreaking step by integrating artificial intelligence (AI) into the sorting process, achieving an unprecedented level of precision. The latest innovation focuses on color differentiation, with AI systems now capable of detecting color differences as subtle as ΔE≤0.5—a threshold imperceptible to the human eye. This advancement is set to redefine quality standards in the pearl industry, ensuring unparalleled consistency and customer satisfaction.

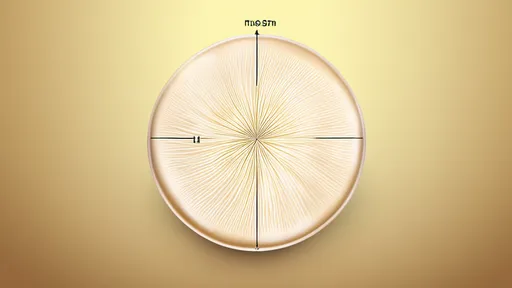

Pearls, unlike other gemstones, derive their beauty from organic processes, resulting in a spectrum of colors that can vary significantly even within the same batch. Traditionally, sorting pearls by color has relied on the expertise of skilled professionals, whose judgments, though refined, are inherently subjective. The introduction of AI-powered sorting machines addresses this challenge by eliminating human error and introducing a quantifiable, objective measure of color difference. The ΔE (Delta E) metric, a standard in color science, quantifies the perceived difference between two colors. A ΔE value of 0.5 is exceptionally low, indicating that the colors are virtually identical under controlled lighting conditions.

The implications of this technological leap are profound for Japan’s pearl industry, which has faced increasing competition from other pearl-producing nations. By adopting AI-driven color sorting, Japanese pearl farmers and distributors can guarantee a level of uniformity that was previously unattainable. This is particularly crucial for high-end markets, where buyers demand perfection in every strand of pearls. The ability to sort pearls with ΔE≤0.5 ensures that matched pearl sets, such as those used in necklaces or earrings, exhibit flawless harmony, enhancing their desirability and market value.

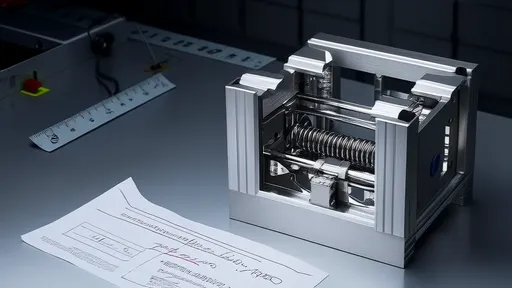

Behind this innovation lies a sophisticated combination of machine learning algorithms and high-resolution imaging. The AI system is trained on vast datasets of pearl colors, learning to distinguish between shades that differ by minuscule degrees. Each pearl is scanned under consistent lighting, and its color profile is analyzed against a reference database. The system then assigns a ΔE value to each comparison, sorting the pearls into groups with nearly identical hues. This process not only improves accuracy but also significantly speeds up what was once a labor-intensive task, allowing producers to meet growing demand without compromising on quality.

Beyond the commercial advantages, the adoption of AI in pearl sorting reflects Japan’s broader commitment to blending tradition with cutting-edge technology. The country’s pearl industry, rooted in centuries of craftsmanship, has embraced innovation to maintain its competitive edge. This synergy of old and new is a testament to Japan’s ability to honor its heritage while pioneering advancements that set global benchmarks. The ΔE≤0.5 standard is more than a technical achievement—it symbolizes a new era in pearl cultivation, where precision and artistry go hand in hand.

As the technology gains traction, its potential applications extend beyond Japan’s borders. Other pearl-producing regions may soon adopt similar systems, raising the bar for quality across the industry. Moreover, the principles of AI-driven color sorting could inspire innovations in other sectors where color consistency is critical, such as textiles, paints, and even digital displays. For now, however, the spotlight remains on Japan’s pearls, where the marriage of nature’s beauty and human ingenuity continues to captivate the world.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025