The medical device industry has long relied on titanium alloys for their exceptional strength-to-weight ratio, biocompatibility, and corrosion resistance. However, the aesthetic customization of these materials—particularly through anodization—has historically been limited to a narrow spectrum of colors. A groundbreaking advancement in low-temperature electrochemical coloring now enables medical-grade titanium components to achieve an unprecedented palette of 200 distinct hues, revolutionizing both functional and design possibilities.

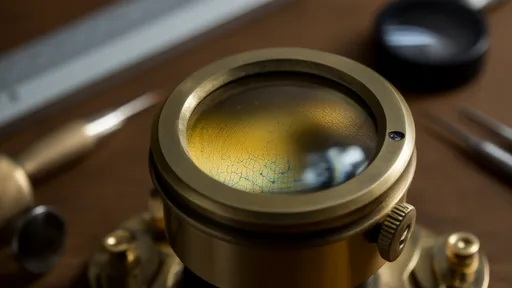

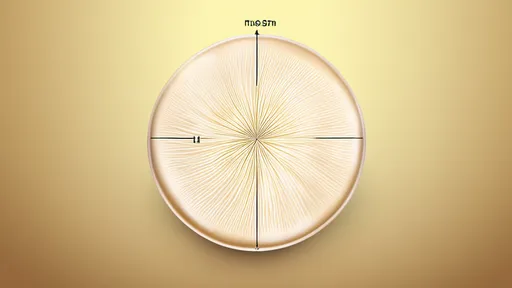

Traditional anodization processes for titanium alloys typically produce colors through light interference effects created by oxide layer thickness variations. While effective, this method restricts outcomes to a predictable sequence of golds, blues, purples, and greens dictated by voltage parameters. The new cryogenic approach decouples color generation from oxide growth kinetics by leveraging controlled electrolyte chemistry at temperatures between -20°C to 5°C. This allows independent manipulation of hue, saturation, and brightness while maintaining the critical surface properties required for implantable devices.

Precision meets artistry in this innovation, where subzero processing conditions enable previously unattainable pastels and earth tones. Medical designers can now match titanium components to skin tones across diverse ethnicities or create intuitive color-coding systems for surgical instrument sets. The process achieves this chromatic expansion without compromising the oxide layer's adhesion strength or bio-inertness—a non-negotiable requirement for ASTM F67/F136 compliant materials.

Behind the technical achievement lies a sophisticated understanding of how low temperatures affect ion mobility in the electrochemical double layer. By slowing down the oxidation rate while introducing organic additives to the sulfuric acid electrolyte, technicians can precisely control light absorption characteristics of the surface. The result is a Pantone-like color library specifically validated for medical applications, where each shade undergoes rigorous testing for cytotoxicity and wear resistance.

Industrial adoption is already underway among orthopedic implant manufacturers seeking to improve patient experience through personalized devices. A hip replacement stem in a bespoke burgundy or a spinal fusion rod in matte olive green—once unimaginable—are now entering clinical trials. The coloring process also demonstrates exceptional stability, with accelerated aging tests showing less than ΔE 1.5 color shift after equivalent to 15 years of UV exposure.

Beyond aesthetics, the expanded color space serves important functional roles. Research indicates that specific hues can reduce patient anxiety when visible in temporary implants, while color-coded components help prevent surgical errors. The technology's repeatability (±0.5μm oxide thickness tolerance) makes it equally valuable for aerospace and luxury watch applications, though medical implementations remain the primary focus due to stringent validation requirements.

As regulatory bodies begin establishing standards for this new coloring methodology, early adopters report an unexpected benefit: the low-temperature process consumes 40% less energy than conventional anodization. This environmental advantage, combined with the elimination of organic dyes previously used to achieve certain colors, positions the technique as both a technical and sustainability breakthrough in medical manufacturing.

The convergence of materials science and color physics embodied in this development suggests broader implications. Future research directions include investigating whether specific color wavelengths could influence osseointegration rates or bacterial adhesion prevention—potentially adding therapeutic dimensions to what began as an aesthetic innovation. For now, the medical world gains a powerful new tool to humanize technology through color, proving that even in high-stakes applications, form and function need not be mutually exclusive.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025